Following on from our article on cooperage , we travelled to Archiac in Charente-Maritime, where we visited our partner, Tonnellerie Allary. They are capable of manufacturing many types of containers, from 1-litre mini-barrels to 34,500-litre truncated vats, 225-litre and 400-litre barrels, etc.

We offer you a tour in pictures, to discover this fascinating know-how, so essential to the breeding and development of our favorite spirits.

The drying park

In the large drying area of the Allary cooperage, you can see pieces of oak in different shapes.

The logs

Logs are almost whole trees, cut into blocks lengthwise. The thickness of these blocks varies: it is 22 mm for the typical 225-litre Bordeaux barrel , 27 mm for the standard international barrel, and can reach 54 mm for large containers.

This is the case of the superb specimen below, which shows an exceptional diameter and length. This log is destined to become a large "premium" tank.

A tank in the making, impressive!

After 3 years of drying, the plots reach 12 to 16% humidity. They can be cut into staves, which once shortened will give staves.

To obtain a stave, we first get rid of the sapwood, the soft part on the periphery. This darker part can be seen in the image.

The heart, hard and cracked, should also be put aside.

The blocks become staves when they are cut to the desired dimensions. It is on this type of bench that they are sawn.

The offcuts are used for various purposes, including firewood for bending or woodworking operations. They can also be used for smaller containers, for bases, or even for aging chips.

These can also be roasted, like coffee beans, to obtain a toasted aroma.

The staves

We are back at the drying yard, where the staves already cut by the stave mill arrive. Upon receipt, they are all checked by hand, with an expert eye. Those that do not meet the quality requirements are returned to the supplier.

We can see that each pallet has its traceability sheet, including the region of origin of the wood, the size of its grain, the split date and the name of the merandier.

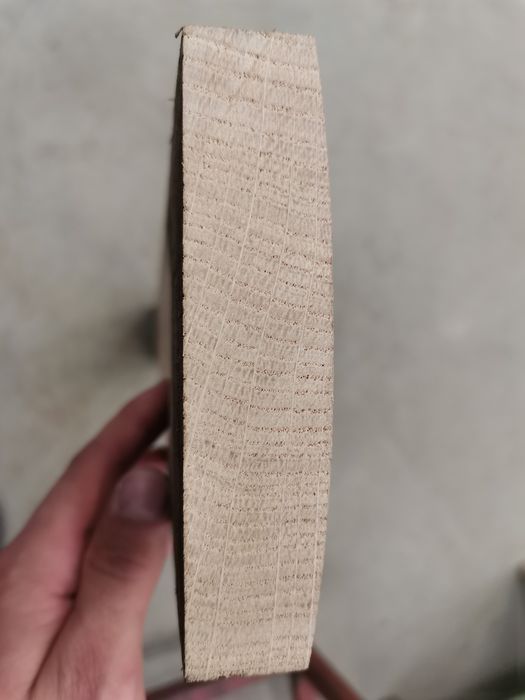

Wood grain is the size of the growth rings, which depends on the tree's growth rate. Here is an example of a fine-grained oak:

And here is a coarse-grained oak:

It is important that the wood is "straight grained", that is to say that it does not have a "sharp grain". The lines of the wood must be very straight, rectilinear. Otherwise, leaks will occur in the barrels .

American oak is an exception to this rule, because despite its sharp grain, it does not cause leaks.

After receipt, the staves dry for an average of 2 years in the Allary park. The most “premium” woods dry at a single height.

From the stave to the stave

It is at the Allary workshop that the perfectly dried staves are transformed into barrel staves. The first operation is the dolage, which consists of giving the piece a sort of trapezoid shape with one side slightly rounded, to give it the shape of the barrel. Later, it will also be hollowed out, to give it a rounded interior.

The staves are placed in a template, the size of which varies depending on the barrel to be made. Thus, staves of varying widths are installed, to reach the exact number of pieces that will make up the barrel.

The rose setting is the first assembly of the staves, around a circle. We see that the ends have been narrowed (by a joining operation), in order to assemble perfectly.

The assembly of the barrel

A first bend is carried out. It allows us to start assembling the bottom of the barrel, in order to send it to the next stage, the real bending.

To completely assemble the bottom of the barrel , it is placed on a heater where it heats up for 45 minutes, until it reaches 150°C. It is then flexible enough to be completely tightened and strapped.

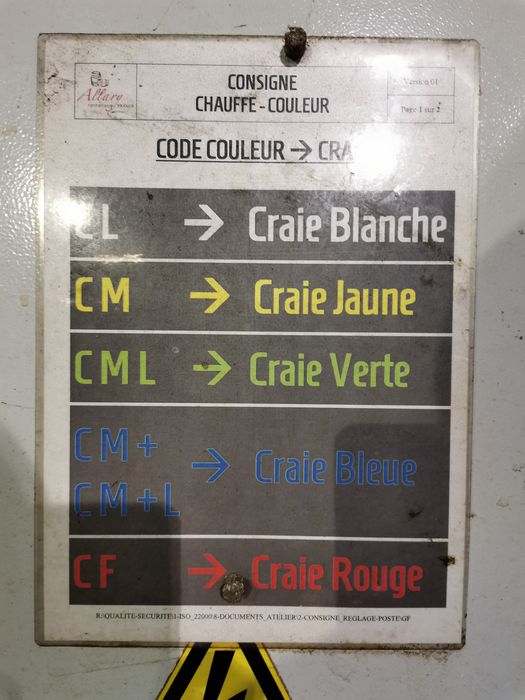

Then comes the boiling, or aromatic heating. The barrels are marked according to the desired heating, with a color code. We can go from light heating to strong heating, including a more or less long medium heating.

1 hour 20 minutes is necessary for a small barrel with light heating, and 1 hour 50 minutes for a large barrel with strong heating.

It should be noted that unlike American cooperages which carbonize the wood with direct contact with the flame, French cooperages use heaters which heat without actually burning.

The Allary cooperage also uses an ingenious system. The hearth is rotating, and also rises and falls, which allows for even heating over the entire internal surface of the barrel.

Here is an ideally heated barrel , which diffuses a superb smell of hot bread:

The finalization of the barrel

It is time to assemble the bottoms, which have been assembled and joined using reed sheets. This traditional technique ensures very good watertightness.

An expert hand then loosens the first circle in order to introduce the funds.

These bases are also joined using a paste made from a mixture of flour and water.

Once the bottom is assembled, the general watertightness is tested. This operation, called scalding, is done with slightly pressurized water. Finally, it is time to add some finishing touches, with a light sanding and a final hooping.

The Allary small barrel workshop

As you know, Rhum Attitude offers you the opportunity to age your own barrels , with small Allary barrels ranging from 1 to 20 liters . Please note that these small barrels benefit from the same know-how and attention as the large ones. Take a look:

Here, the staves have calibrated widths. They benefit from the same operations of smoothing and hollowing out.

We also observe the joining (the narrowing of the ends) which allows them to be assembled for the rose arrangement.

Once this pinking has been carried out, the barrels are bathed for a few minutes in hot water, in order to soften the staves.

Then they are instantly dried in order to be shaped and hooped.

This is followed by a proper roasting, an aromatic heating which will allow the wood to express all its aromas during aging.

The bottoms are then placed, and the barrels are completely hooped.

Several finishes are available. You can receive a waxed barrel inside, in order to slow down the effects of aging. A varnish can also be applied, for aesthetic purposes, but also to slow down aging to a lesser extent.

Personalized engraving is also offered, as well as specially prepared cognac barrels .

Up to you !

Now you know how your barrels are made. You are ready to have your own cellar master experience. A large selection of white rums is available to you on the site, and you can even have fun blending several rums!

Don’t hesitate to get started and tell us about your experiences!

It’s a shame that the cooperage is not able to offer “ex-barrels” like Navarre.

Sincerely

Well, precisely, we also offer 5-litre barrels prepared with cognac 😉 https://www.rhumattitude.com/cave/fut-de-vieillissement-neuf-allary-5-litres-ex-cognac/