Whether in the field of agricultural rums or in that of molasses rums, fermentation is a key step that will determine the final character of the rum. We will come back to this in more detail in a future article, but you should know that distillation is actually the art of selecting the nature and quantity of aromas that we want to obtain in our rum, by controlling their evaporation and condensation at the exit of the still. However, it is during fermentation that most of these available aromas will form, to then be selected by the distiller.

It is also of course a question of obtaining an alcoholic fermentation , that is to say of allowing the yeasts to transform the sugar contained in the must (pure cane juice or diluted molasses) into alcohol. This alcohol will be concentrated during distillation and will take with it a whole bunch of aromatic molecules linked to it. Some aromas are called " primary ", because they come from the raw material, while the aromas resulting from fermentation are the " secondary " aromas. The " tertiary " aromas, as you will have understood, are the aromas obtained during aging.

Prepare for fermentation

For the fermentation of pure cane juice , the latter is slightly diluted when crushing the stalks which are watered in order to maximize the extraction of sugar. Note that unlike cane intended for sugar, cane intended only for rum distillation is harvested a little before its complete maturity. The stalk must not be at its maximum sugar content so that there are other elements which the yeasts will feed on throughout the process.

The molasses is also diluted, and even more significantly because its very viscous consistency will have to be liquefied for the next stage of distillation. About 50% of its material is composed of sugar , so the remaining half will be enough to feed the yeasts.

A very important and rather delicate point is that of acidity . To produce aromatic molecules, yeasts will bind acids to the alcohol they produce. However, too much acidity can prevent good fermentation, and on the other hand a lack of acidity can promote bacteria that will be the origin of undesirable aromas or that will prevent the formation of alcohol. However, certain bacteria are necessary for the appearance of interesting aromas, and we do not necessarily seek to eradicate them. We therefore seek above all balance by adding acid in carefully studied quantities adapted to the environment.

The temperature is also controlled because too much heat “puts the yeast to sleep” and leads to a drop in yield in quantity as well as in aromas.

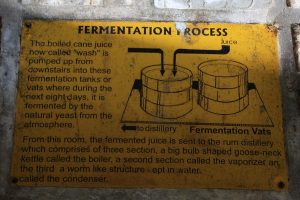

Traditionally, before industrialization, natural and wild (spontaneous) fermentation was allowed to take place, using yeasts naturally present in the environment. But these fermentations gave random results, they took time and did not offer sufficient yields. The scum that formed on the surface of the vats was then used to reintroduce them during the next fermentation. The results thus obtained were more regular but still imperfect. It was therefore decided to control the process further by introducing industrial yeasts , most of the time from bakeries or breweries.

Some distilleries like Neisson have selected and developed their own endemic yeast strains and thus best reflect their terroir.

Yeasts are raised and maintained in mother tanks , then the fermentation tanks are inoculated with yeasts that are well concentrated and acclimatized to the environment, so that fermentation can begin!

Light rums and heavy rums

A distillery is often able to produce different types of rum , either to offer rums intended for different types of consumption (cocktails vs tasting), or to make balanced blends. To do this, it can produce light rums or heavy rums . We sometimes confuse a light rum in alcohol and a light rum in aromas.

In the world of rum, light rums are rums that have a reduced quantity of aromatic molecules or rums whose molecules are very volatile.

Conversely, a heavy rum will be a rum with a high concentration of aromas, or a rum with very heavy aromatic molecules.

Fermentation is a big part of deciding whether to produce a light rum or a heavy rum, and here are some ways to influence the outcome:

– Sterilization of the raw material: if the pure juice or molasses is free of bacteria, the yeasts will produce a very pure alcohol and therefore a light rum.

– The addition of yeasts in bulk to kill any bacterial competition, in order to produce a light rum.

– Temperature control : the lower the temperature, the more the fermentation will produce aromatic molecules, and therefore a heavy rum.

– Fermentation in closed or open tanks : the issue is to admit or not bacterial contamination . The fewer bacteria there are, the lighter the rum will be, and vice versa. Note that pure cane juice is naturally richer in bacteria inherited from the bark and fiber of the cane. Molasses is an industrial product cooked several times, it contains much fewer bacteria, so an addition is necessary in most cases.

– The duration of fermentation : typically, the shorter the fermentation, the lighter the rum will be. Fermentations of very light rums last on average 12 hours, compared to 24 to 72 hours maximum for AOC Martinique rum, and a week or even 10 to 15 days for certain Jamaican rums for example. Once again, it is during this period that the yeasts fight with the bacteria and that the aromas are created.

The challenge is to find the right balance , that is, to obtain the best yields in time and quantities without sacrificing the aromas , character and typicality of the rums. In other words, this is where the line lies between profitability and respect for the product and consumers.

Be careful, this is not to create a division between light rums and heavy rums, each having its interest according to its mode of consumption and its use in a blend. But extreme purification, if it is profitable, presents the danger of removing all the personality and all the specificity of what a rum is.

High esters and great aromas

So-called " high ester " rums are very heavy and highly concentrated molasses rums that often far exceed classic traditional rums in terms of aromatic concentration. To be a little technical, a traditional rum contains at least 225 grams of non-alcoholic elements per hectoliter of pure alcohol, while a high ester contains at least 500 (the most loaded ones contain 1500).

These ultra-concentrated rums are intended to enhance blends, and even for other areas such as the food industry where they are used in the composition of pastry flavors, etc.

It is the fermentation techniques that are first and foremost at the origin of these types of rum. Everything is done to ensure that this fermentation is as efficient as possible in terms of aromas: duration, temperature control, bacterial contamination, etc.

These high esters are often produced by traditional English distilleries: Saint Lucia Distillers, Long Pond, Demerara Distillers Limited, etc. To learn the difference between the different traditions, read our article on rum making and rum styles .

In this category of high esters, we find a family inherited from the early days of rum: grand arôme rums . Their main singularity is that instead of using water and acids to dilute and prepare the must, vinasse (very acidic residue from previous distillations) is used. Fermentation is spontaneous , without the addition of external yeast, which means that the room where the fermentation takes place is a breeding ground, an ecosystem built over decades where bacteria and yeasts are everywhere. They will fight for 1 to 2 weeks and will thus produce complex and concentrated alcohols (under the stress of this battle, the yeasts bind even more acids to the alcohols, which produces even more aromatic molecules).

Only three distilleries still practice this traditional fermentation: Le Galion in Martinique, Savanna in Reunion and Hampden in Jamaica.

“Primitive” or very artisanal rums

Some distillers still work as they did in the early days of tafia and guildive , with spontaneous, long and very poorly controlled fermentations . This is the case of Clairins from Haiti, grogue from Cape Verde, or small distillers from South America like the Mexicans from Paranubes. Their rums are very aromatic but their yields are much lower and more random than in larger-scale distilleries where fermentation is controlled and rationalized.

The result is very authentic products, different from one year to the next and even from one batch to the next, which makes them particularly appealing.

Wonderful article,

Thanks for Nico (the editor)

Excellent article that answers all my questions!

THANKS !

Very good article. Thank you.

It makes me want to try cachaça!

Thank you Raul for this comment, and especially thank you for your cachaça of which we are great fans!

I really enjoyed your document, it's up to me to try the production of rum. Thank you.

THANKS

…Super interesting article!